Understanding Low Profile Junction Boxes

Low profile junction boxes, also known as under-cabinet junction boxes, are essential components for electrical wiring in kitchens, bathrooms, and other areas where space is limited. These boxes are designed to be discreet and unobtrusive, seamlessly blending into the surrounding environment. They offer a safe and organized way to connect electrical wires and devices while maintaining a clean and aesthetically pleasing appearance.

Purpose and Benefits

Low profile junction boxes serve a crucial purpose in simplifying electrical wiring and ensuring safety in under-cabinet installations. Their compact design allows for efficient use of limited space, making them ideal for areas where traditional junction boxes would be too bulky. These boxes provide a secure and organized way to connect wires, reducing the risk of loose connections and potential electrical hazards.

- Space Optimization: Low profile junction boxes are designed to fit snugly under cabinets, maximizing space utilization and minimizing visual clutter. They are particularly useful in areas where traditional junction boxes would protrude too far, creating an obstruction.

- Safety and Organization: These boxes provide a secure and organized environment for electrical connections. The enclosed design protects wires from damage and prevents accidental contact, enhancing electrical safety. The compartmentalized structure allows for easy wire management, reducing the risk of tangled or loose connections.

- Aesthetic Appeal: Low profile junction boxes are typically designed to blend seamlessly with the surrounding environment, maintaining a clean and aesthetically pleasing appearance. They are often available in various finishes, such as white or black, to match the décor of the space.

Design Features

Low profile junction boxes are engineered to accommodate specific requirements for under-cabinet installations. Their design features are crucial for ensuring functionality, safety, and ease of use.

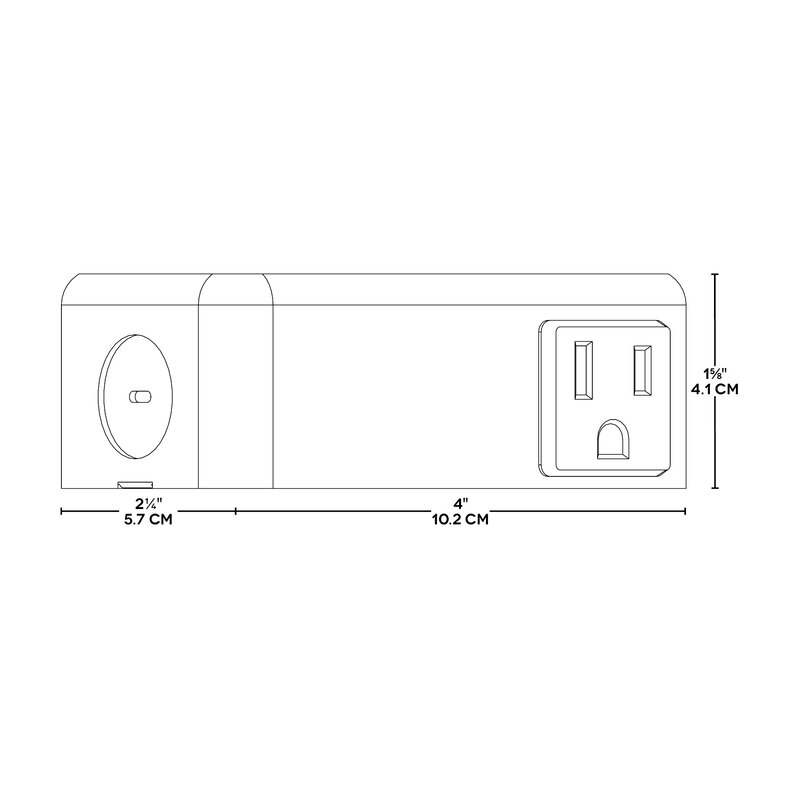

- Compact Size: These boxes are designed to be compact and thin, allowing them to fit comfortably under cabinets without obstructing access or creating a visual distraction.

- Secure Mounting: They typically feature mounting tabs or brackets that allow for secure attachment to the underside of cabinets. This ensures stability and prevents the box from falling or becoming dislodged.

- Multiple Entry Points: Low profile junction boxes often have multiple entry points for wires, facilitating easy connection and routing. This flexibility allows for various wiring configurations and simplifies the installation process.

- Cover Plates: These boxes often include cover plates that provide a clean and finished look. The cover plates can be easily removed for access to the wiring, making maintenance and troubleshooting convenient.

Common Applications, Low profile junction box under cabinet

Low profile junction boxes are versatile and find widespread applications in various electrical installations, particularly in residential and commercial settings. Their compact design and ease of installation make them ideal for a range of scenarios.

- Under-Cabinet Lighting: These boxes are commonly used to connect under-cabinet lighting fixtures, providing a safe and organized way to manage the wiring for LED strips or puck lights.

- Electrical Outlets: Low profile junction boxes can be used to accommodate electrical outlets under cabinets, offering convenient access to power for small appliances or charging devices.

- Home Automation: These boxes are suitable for connecting smart home devices, such as motion sensors, light switches, or remote controls, under cabinets, providing a discreet and functional solution for home automation systems.

- Kitchen Appliances: Low profile junction boxes can be used to connect appliances, such as garbage disposals, dishwashers, or refrigerators, under cabinets, simplifying wiring and ensuring safety.

Installation and Wiring Considerations: Low Profile Junction Box Under Cabinet

Installing a low-profile junction box under a cabinet is a relatively straightforward process that can be accomplished with basic tools and some knowledge of electrical wiring. This section will guide you through the steps, ensuring a safe and efficient installation.

Choosing the Right Location

The location of the junction box is crucial for ease of access and optimal performance. The box should be positioned where it is easily accessible for future maintenance or modifications. Ideally, it should be located near the power source and the electrical components it will be connecting.

Step-by-Step Installation Guide

- Prepare the Area: Before installing the junction box, ensure the area is clear of any obstructions and that the power is turned off at the circuit breaker. This is a crucial safety precaution to prevent electrical shock.

- Mark the Location: Use a pencil to mark the desired location for the junction box on the underside of the cabinet. Ensure the box is level and positioned in a way that allows for easy access to the wiring.

- Drill Pilot Holes: Using a drill bit slightly smaller than the diameter of the screws provided with the junction box, drill pilot holes at the marked locations. This will prevent the wood from splitting when you drive the screws in.

- Secure the Junction Box: Align the junction box with the pilot holes and use the screws to secure it to the cabinet. Ensure the box is securely fastened and that it is level.

- Run the Wires: Carefully run the wires from the power source and the electrical components to the junction box. Make sure the wires are routed in a way that avoids sharp corners or excessive strain. Use wire staples or clips to secure the wires along the route.

- Connect the Wires: Inside the junction box, connect the wires to the appropriate terminals. Ensure the wires are properly stripped and that the connections are secure. Use wire nuts to connect multiple wires together.

- Test the Connections: After making the connections, carefully test the circuit for continuity and proper operation. Use a non-contact voltage tester to ensure that the power is off before proceeding. Once the connections are confirmed, turn the power back on at the circuit breaker.

- Cover the Junction Box: After the connections are tested, install the cover plate over the junction box. Ensure the cover plate is securely fastened and that it covers the entire opening of the box.

Wiring Considerations

- Wire Types: Use wire types that are appropriate for the application and the current rating of the circuit. For most under-cabinet lighting applications, 14-gauge or 16-gauge wire is suitable. Always consult local electrical codes for specific requirements.

- Connections: Make sure all wire connections are secure and properly insulated. Use wire nuts or terminal blocks to connect wires together. Avoid overloading the junction box with too many wires.

- Safety Precautions: Always work with electricity with caution. Turn off the power at the circuit breaker before working on any electrical wiring. Use appropriate tools and safety equipment, such as insulated gloves and safety glasses.

Types and Features of Low Profile Junction Boxes

Low profile junction boxes are designed to be discreet and space-saving, making them ideal for applications where aesthetics are crucial. They come in various designs and functionalities to accommodate different wiring needs and project requirements. Understanding the different types and features of these boxes is essential for selecting the right one for your specific application.

Construction and Material

The construction of a low profile junction box is a significant factor determining its durability, water resistance, and overall performance.

- Plastic Junction Boxes: These are the most common type, often made from ABS or PVC. They are lightweight, affordable, and easy to install. They are suitable for indoor applications where moisture is not a concern.

- Metal Junction Boxes: These boxes are made from materials like steel or aluminum, providing greater durability and resistance to damage. They are suitable for outdoor applications or areas with high traffic or potential for impact. Metal boxes are also better at dissipating heat, making them suitable for installations with high-power wiring.

- Combination Boxes: These boxes combine the features of plastic and metal construction. They may have a plastic housing with a metal cover for added durability or a metal housing with a plastic lid for easier installation.

Capacity and Wiring

The capacity of a low profile junction box refers to the number of wires and devices it can accommodate.

- Number of Knockouts: Knockouts are pre-drilled holes in the box that allow you to feed wires into the box. The number of knockouts determines the number of wires you can connect to the box.

- Wire Gauge: The wire gauge refers to the thickness of the wire. Different junction boxes are designed to accommodate specific wire gauges. Ensure the box you choose can handle the wire gauge you are using.

- Device Capacity: Some low profile junction boxes are designed to accommodate specific devices, such as switches, outlets, or dimmers. Check the box specifications to ensure it can accommodate the devices you need.

Features and Considerations

Several features can enhance the functionality and ease of installation of low profile junction boxes.

- Clamps and Connectors: Some boxes come with built-in clamps or connectors for easier wiring. These features simplify the connection process and improve the overall reliability of the installation.

- Cable Management: Features like internal dividers, cable clamps, or strain relief devices help manage and organize wires inside the box. This makes the installation neater and more organized.

- Water Resistance: Low profile junction boxes are available with varying levels of water resistance. For outdoor applications or areas with potential moisture exposure, select a box with a suitable ingress protection (IP) rating.

- Fire Resistance: Some boxes are designed to be fire-resistant, providing added safety in areas where fire hazards are a concern.

Low profile junction box under cabinet – Low profile junction boxes are often used in kitchens to provide discreet access to electrical outlets under cabinets, particularly in spaces where aesthetics are important. This is especially true when incorporating appliances like a double oven, as seen in the selection of double oven cabinets at Lowe’s.

The junction box allows for the wiring to be concealed, maintaining a clean and organized look within the kitchen’s design.

Low profile junction boxes installed beneath kitchen cabinets offer a discreet and functional solution for electrical outlets and wiring. This design element seamlessly integrates with the modern trend of modular kitchen cabinets without handles , maintaining a clean and minimalist aesthetic.

The junction box’s low profile ensures it remains hidden from view, while providing easy access to power sources for appliances and other kitchen necessities.